KEMEX working with AMEC INTERNATIONAL and Andacollo Mining TECK designed and built a solution for copper concentrate shipment.

We encountered a problem in Puerto Coquimbo Chile. In this port Compania Minera Teck Carmen de Andacollo you export copper concentrate.

The copper concentrate is incorporated into the ship loading belt through a hopper that directly falling on the conveyor belt, but caused continuous loadin belt stops. The main causes were:

- The wet copper concentrate is not get dosing.

- The material in the hopper caused vaults.

- The loading of ships by the 'stop lengthene

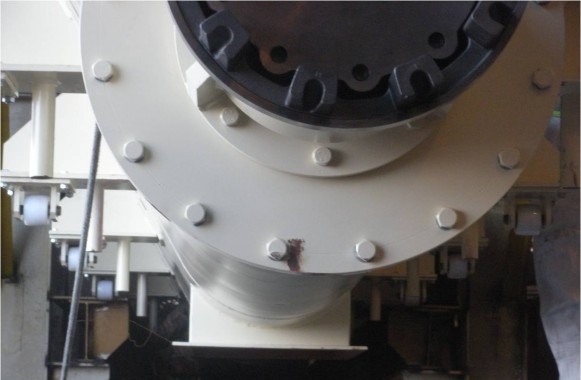

We designed a hopper and a screw of the following features:

FUNCTION

Material discharge from loaders to a conveyor belt. The hopper collecting material, and the screw dosing the discharge of material to the conveyor belt. In the hopper is placed nonstick material, which allows the sliding of the material, the screw design prevents the formation of domes, carrying the material to a central discharge area.

DESIGN

- Capacity: 1,000 t / h.

- Product Density: 2.2 tn/m3, copper concentrate.

- Screw Length: 6.100 m.

- Coil diameter: 550 mm.

- Hopper Volume: 10 m3.

Related technologies

- Previous

- Next

Related products

- Previous

- Next