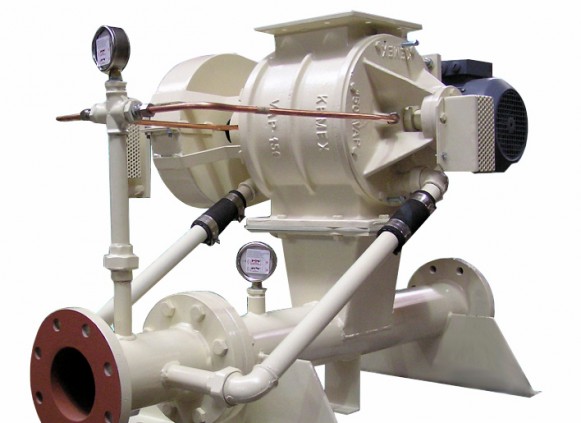

VAP rotary valves are suitable for low-pressure – less than 1 bar – pneumatic conveying and include an intake connection for coupling to the conveying pipeline.

Air is introduced into the conveying pipeline by a blower.

They are composed of a closed body with side covers, with an upper opening for introducing material inlet and a lower outlet, with a rotor composed of blades forming cavities rotated by a geared motor.

The closures are pressurized and thus seal the equipment hermetically.

These are used to convey low-abrasion products. Currently, our VAP valves are working with products such as:

• PVC resin powder

• Polystyrene pellets and powder

• Polystyrene pellets and powder

• Sodium carbonate

• Coke powder

• Hydrated lime

• Perborate

• Plaster

• Gypsum

• Limestone powder

• Sawdust

• Flours

Advantages of VAP rotary valves for pneumatic conveying

• Capacity of up to 200 t/h

• Working pressures below 0.6 bar

• Made of carbon steel, cast iron, aluminum or stainless steel

• With sealed bearings separated from the covers

• Pressurized closures and compression gland

Related technologies

- Previous

- Next

Related industries

- Previous

- Next

-

Marine

Our experience in the cement industry has allowed us to…

Our experience in the cement industry has allowed us to…

-

Chemical Industry

We design installations for handling chemical products in different production…

-

Mineral Industry

We provide numerous solutions for handling minerals in different production…

We provide numerous solutions for handling minerals in different production…

-

Cement Industry

This is the industry where Kemex began, and in which…