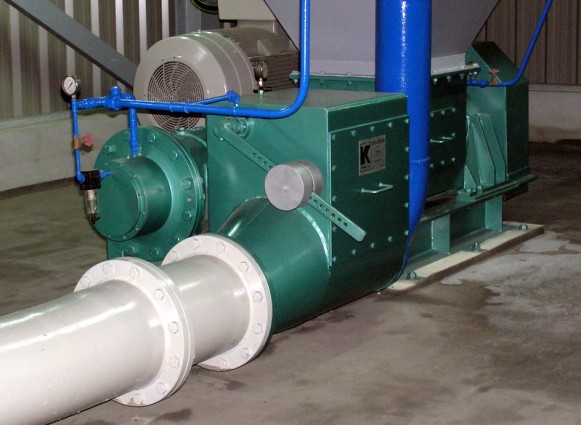

Kemex’s KX pump is designed for the pneumatic conveying of dry products using medium-pressure air. It allows for a wide range of transport distances and capacities.

The Kemex screw pump is the solution for installations requiring continuous conveying for large capacities of material.

The products to be conveyed are powdered products that are needed to be conveyed in the chemical cement industry.

KEMEX KX pumps convey products such as:

- Cement

- Cement raw materials

- Electrostatic powder

- Coal powder

- Ash

- Slag powder

- Limestone

- Carbonate

The product enters the Kemex KX pump via its feed hopper, from where it moves towards the outlet via an auger screw operated via transmission that introduces the product into the conveyor line, avoiding any air leakage.

As soon as the material passes into the mixing chamber, it is fluidized by medium-pressure air from a compressor or blower, and directed through the pipe to the reception point.

The auger screw is supported at both ends on external bearings sealed by mechanical elements and air. The augers are reloaded depending on each application in anticipation of the wear caused by the product’s abrasiveness.

Advantages of the Kemex KX screw pump:

- Conveying capacities of up to 400 t/h

- Conveying distances of up to 1,000 m

- Conveying pressure of up to 2 bar

- Designed for abrasive materials

- Auger screw supported at both ends

- Three-direction alternative unloading